| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : WGM&Weili

Model Number : LBW2000PB

Certification : CE&SGS&BV

Place of Origin : China

MOQ : 1 set

Price : USD 23000-75000/SET

Supply Ability : 200 sets per year

Delivery Time : 35 work days

Packaging Details : 1.Machine packing with plywood pallet or according to customers` requirements 2.In plywood pallet and plastic film 3.In container

Name : Insualting glass machine

Usage : Making insulating glass

Color : Blue or customize

Dimension(LXWXH) : 21300x2800x3300mm

Power supply : 34kw

Min.glass size : 300x400mm

Max.glass size : 2200x3000mm

Warranty : 1 year

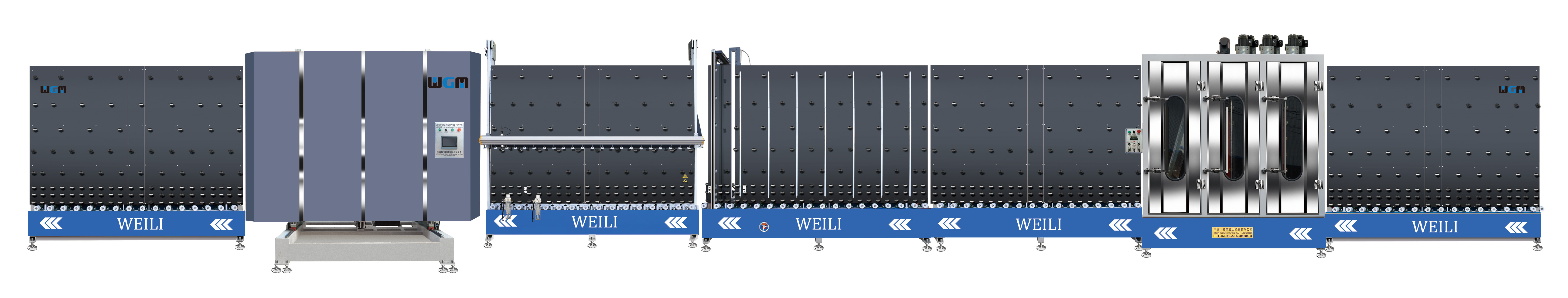

20 Meters Length 380V 50HZ Insulating Glass Machine For Glass Processing

This line can be upgrated and expanded according to customer is demands.

Usage:

LBW2000PBVertical Automatic Insulating Glass Outside Assembly Flat Press Production Line is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance.It has seven parts:

1 input section

2 washing section

3 inspecting section

4 spacer location section

5 outside assembly section

6 press section

7 output section

Features:

1. Whole process with PLC control system, man-machine interface touch screen .

2. Adopt Japan Keyence coating detection switch, automatic identification of coated glass and LOW-E glass.

3.Washing machine, dryer shell made of high quality stainless steel material.

4. Upper drive in washing section, avoid water leakage of the sealing parts aging .

5. Each brush with separate motor control (six brush ,six motor )

6. Adopt Janpan SMC vacuum generator and sucker, nineteen suckers are in a reasonable partition, glass suction effect will be better.

7. Inner panel assembly and outer panel assemble ,two sets program ,ideal equipment for insulating glass and curtain wall.

8 .Seven frequency control result in reasonable transportation and efficient production.

9 . All photoelectric switches are supplied by Korean Autonics, ensure more

accurate positioning.

10. Inner panel assembly and outer panel assemble ,two sets program ,ideal equipment for insulating glass and curtain wall.

11. The speed reducer adopt precision casting aluminium, turbine are made

of casting tin bronze material

12. All bearings are from SKF, rotation is flexible without noise.

13. The conveying wheel is polyurethane materials, wear resistance and low noise.

14. The backup plate in transport line are Dew River moisture-proof plate,

beautiful, generous, damp proof.

15. All conveying shaft with grinding processing, flange processing, corrosion prevention to ensure the precision of the main shaft, equipped with high quality bearing, so the glass conveying is stable, high speed.

16. The rubber roller transmit as a whole in the cleaning machine , automatically adjust the distance between the two rollers according to the different thickness of glass

17. The brush are high quality 1010 nylon yarn, it can clean coated glass, the shaft head are stainless steel; brush filaments are close, ensure the glass cleaner .

18. Reasonable air knife angle design ,easy to adjust the angle and distance and ensure the blowing effect is better

19. Aluminum frame positioning adopt longitudinal, horizontal positioning and is adjustable , so that the aluminum frame positioning more accurately and conveniently, easy for one person operate large aluminium frame.

20. Low noise circulating wind system, and equipped with damper(air brake) function, has the effect of energy saving.

21. Siemens servo motor, ball screw control the size precision.

22. The large-stroke of pressing section can be pushed to 550 mm, convenient for maintenance

23.According to the different requirements of customers can realize unequal sheets and three sheets of glass production.

| Power Supply | 380V 50 HZ 35KW |

| Dimension (L x W x H) | 18390mmX2500mmX2950mm |

| Production quantity | 700-800IG units/8hs |

| Max glass size | 2200mmx3000mm |

| Min glass size | 300mmx400mm |

| Washing glass thickness | 3-15mm |

| Washing glass speed | 0-10m/min |

| Insulating glass thickness | 48mm(can adjust) |

| Transmission glass speed | 45m/min |

| Compress air | 0.8m³/min |

| Air pressure | 0.8Mpa |

Main components:

| NO. | Name | Brand | Brand Place |

| 1 | PLC | OMRON | JAPAN |

| 2 | 10.0 inch touch screen | KINCO | TAIWAN |

| 3 | Photoelectric switch | AUTONICS | KOREA |

| 4 | Limit switch | AUTONICS | KOREA |

| 5 | Transducer | TAIAN | TAIAN |

| 6 | Vacuum generator&sucker | SMC | JAPAN |

| 7 | Low voltage electric components | AIRTAC | TAIWAN |

| 8 | Solenoid valve | AIRTAC | TAIWAN |

| 9 | Cylinder | AIRTAC | TAIWAN |

| 10 | Liner guide rail | HIWIN | TAIWAN |

| 11 | Bearing of cleaning section | SKF | SWEDEN |

| 12 | AC digital servo motor | TECO | TAIWAN |

| 13 | Transmission motor | CPG | ZHEJIANG |

| 14 | Hydraulic Parts | HUA DE | BEIJING |

| 15 | Gas-type Filling | AIRTAC | TAIWAN |

| 16 | Oil pump | JILI | TAIWAN |

| 17 | Servo motor | SIEMENS | GERMANY |

Packing & Delivery:

1.Machine packing with plywood pallet or according to customers` requirements

2.In plywood pallet and plastic film

3.In container

|

|

34kw LOW E Glass Manufacturing Machinery And Equipment PLC Control System Images |