| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : WGM&WEILI

Model Number : LBW2500PC

Certification : CE&BV&SGS

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 25 sets per month

Delivery Time : 35days

Packaging Details : plastic film and plywood pallet

Name : Argon gas filling machine

Usge : fill argon gas

Color : Blue and Black(can customize)

Warranty : 1 year

After srvice : Online support ,Video technical support

Total power : 34kw

Voltage : 220V

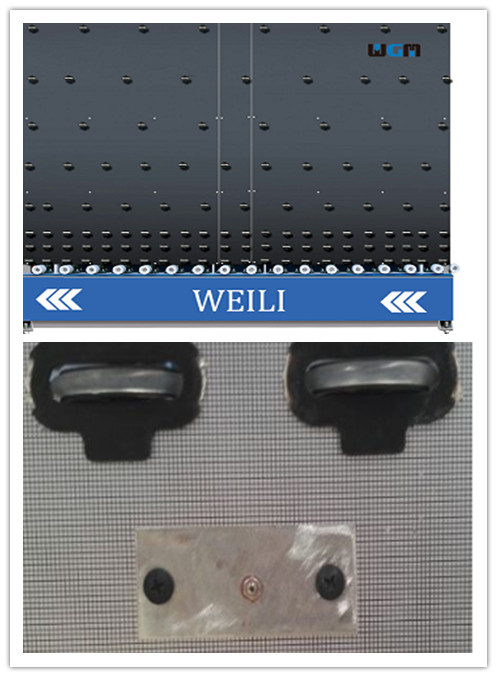

LBW2500PC-07 vertical 2500mm Automatic Argon Gas Filling Production Line For Insulating Glass

Main feature

adopt PLC control the working condition, this production line can produce Low-e glass, double glazing , triple glazing and step glazing.Which include 7 sections, that is feeding section., washing and drying section, storage section, light inspection section and spacer bar put section, assembly section ,press section ,output section.

Specification:

1 The glass panels are made of high density board which can resist the moisture.

smooth panel and Low-e coating checking system.

2 washing and drying section

2.1 whole washing section is made of stainless steel,avoid rust

2.2 6 pieces nylon soft brushes avoid scratch the glass

2.3 CNC bending air knife, so it can be strength the motivity of the wind and make the drying effect obtain the best

2..4 water tank is equipped with water heating device and water filtering system, guarantee the glass washing temperature and cleanness.

2.5 Sensor install before the press to measure glass height so that press will fill gas according to glass size ,then save more gas

3 Press and argon gas filling secton

3.1 18 SMC Gas filling solenoid valve to supply gas source to gas filling hole

3.2 SIEMENS servo motor drive screw rolls and control press section open and close

3.3 Press can open 450MM for maintenance

Technical parameter

|

Technical Parameter | LBW2500PC -07 Vertical insulating glass automatic gas filling production line |

| Min glass size | 400*450mm |

| Max glass size | 2500*3500

|

| Washing glass thickness | 3-12mm |

| Washing glass speed | 2-12m/min

|

| Power supply | 380V/50HZ 38KW |

| Insulating max glass thickness | 50 mm

|

| Transmission glass speed | 45 m/min

|

| Air pressure | 1Mpa |

Main electric components

| Name | Brand | Origin |

| PLC | SCHNEIDER | GERMANY |

| transducer/frequency changer | SCHNEIDER | GERMANY |

| circuit breaker | SCHNEIDER | GERMANY |

| contactor | SCHNEIDER | France |

| relay | OMRON | Japan |

|

Washing and drying section |

Stainless steel |

304 stainless steel |

| Brush | Soft brush | 101 nylon soft brush |

| Optoelectronic switch | Autonics | Korea |

| solenoid valve | AIRTAC | Taiwan |

| Servo motor | SCHNEIDER | Germany |

After sales service

1 Online support,for example email and open camea to solve problems

2 Field installation, commissioning and training

3 Field maintenance and repair service

4 Video technical support

|

|

Vertical 2500mm Insulating Glass Machine 34kw Total Power With 1 Year Warranty Images |