| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : WEILI

Model Number : LBW1800PB

Certification : CE,,SGS,ISO 9001,SGS&CE&BV

Place of Origin : CHINA

MOQ : 1set

Payment Terms : T/T

Supply Ability : 20sets/month

Delivery Time : 30 working days

Packaging Details : plastic plywood and wooden package

Function : Vertical Automatic Flat Press Insulating Glass Produce Line

Max glass size : 3~15mm

Glass thickness : 3-68mm

After-sales service provided : Engineers available to service machinery overseas,Field installation,commissioning and training,Video technical support,Field maintenance and repair service

Name : Vertical Automatic Flat Press Insulating Glass Produce Line

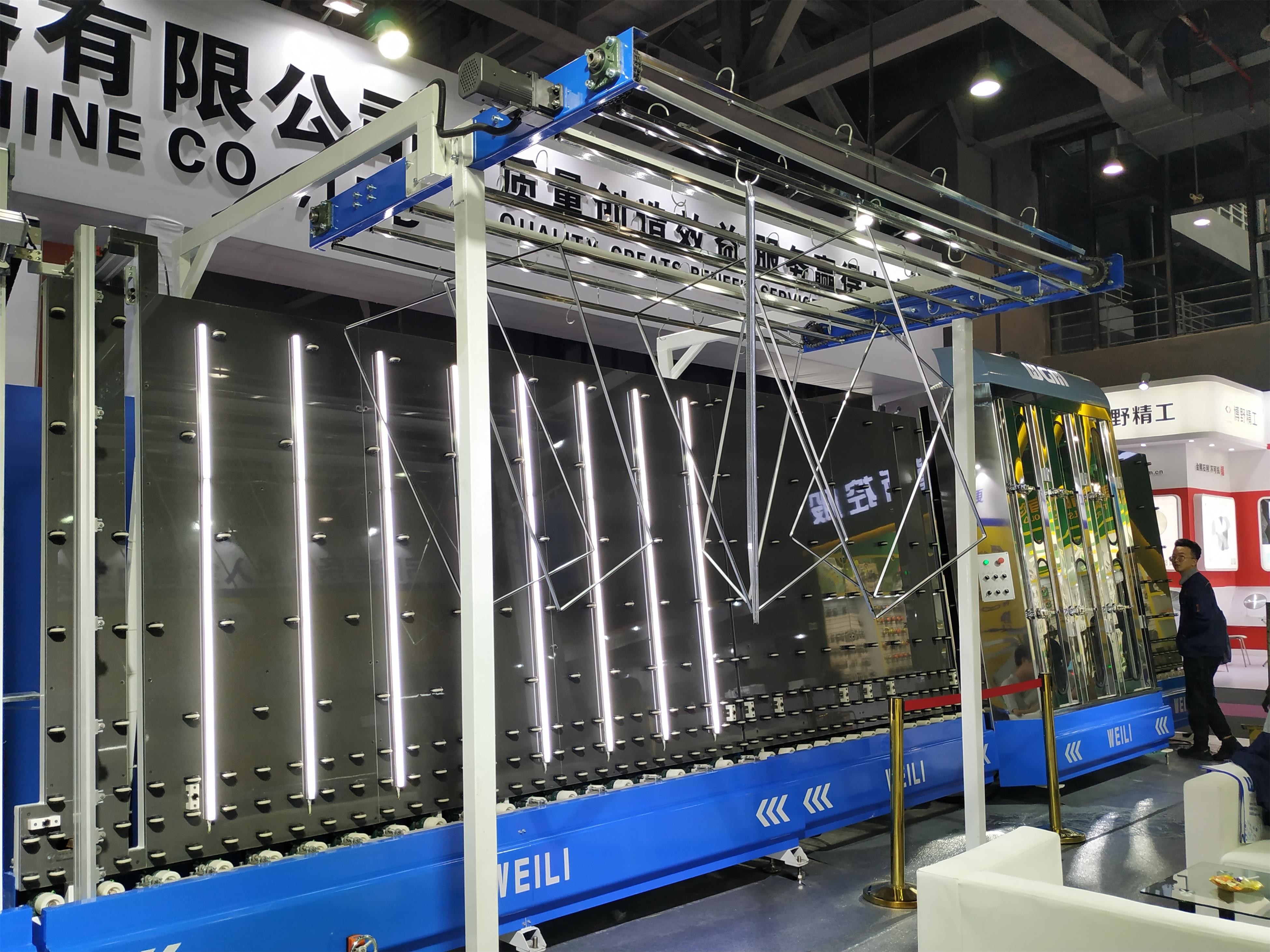

Automatic Flat Press Insulating Glass Machine High Speed Produce Smooth Running

Double Glazing Glass Production Machine Line For Insulating Glass Processing is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance.

1.Structure and Function for Each Part.

Following is our machine details.And then it is our machine pictures,our factory pictures.

Check it,find more information.Any question,also can send the requirment for us directly.We can reply you in one hour.

This production line comprises the stainless steel washing machine,spacer attaching,automatic outside assembly,automatic flat press,glass storage section.This line can be upgrated and expanded according to customer is demands.

This line is controlled by PLC and realizes the automatic control and frequency control of the motor speed of the whole line. It adopts advanced assembly technique and solves the problems of uneven press and misplacement of the glass. The assembly section adopts limit switch and cylinder tank whose travel distance can be adjusted, making the operation easy and the location precise and the movement reliable.

There are two operation methods in the control panel: ‘automatic’ and ‘manual’. If the separate operation of each section or maintenance is needed, the ‘manual’ operation method is needed.

2.The structure and function of each section are as following.

(1) The entire machine’s operation uses the man-machine contact surface (it has Chinese and English languages):

Operates direct viewing and convenient, the running status is dynamic demonstration, the frequency conversion velocity modulation; the maximum speed may amount to 45 meters/Minute.

(2) High production efficiency: The big glass can move at the full speed, the small glass is possible to stop in storage area, and stay at the storage area temporarily, also the clean glass may input continuously.

(3)Conserves energy interrupted type automatic operation system:

Entire machine uses the energy conservation interrupted type automatic operation system, when glass movement to the photoelectric sensor of the end of the input conveyor, the brush, the water pump, the air blower will be start automatically, when the production is interrupted, the brush, the water pump, the air blower will automatically stop, the section of the equipment which was occupied moves in full speed, other parts which do not work are at the intelligence dormant state, so it is energy saving.

3.The whole process for the insulating glass untis making

4.Insualting glass Machine process in weili factory

5.Machine is customer factory

6.FAQ:

1. Are you a manufacturer?

Yes,we have been in providing the professional products in this field for 10 years.

2. how to install the machine ?

we can intrust the install the machine by vedio, email ,picture.....if large project ,

we can arrange the worker help you to install it in your country .

3. How you pack the products ?

Normally as the export standard packaging or as you required.

4. What is your available port of shipment?

Qingdao port,shanghai,tianjin,guangzhou etc.

5. Is customized available ?

Yes, according to your detailed drawings you provide

6. After Sale Service

24 hours technical support by phone, email or skype (email or skype) .

12 months warranty period.

Our senior engineer is available to travel aboard, help the installation, maintenance and

training staff.

By offering this support, we make sure the customer start the business smoothly,

to realize win-win cooperation

7. Are you trading company or manufacturer ?

We are factory and welcome to visit us at any time.

8. How long is your delivery time?

Generally single tanks need 15-30 days, for whole plant need 30-50days.

9.Do you have CE and UL certification?

Yes.

10.What is your terms of payment ?

Free contact for the most suitable machine

Free professional design for each customer especially.

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union or Paypal.

|

|

Automatic Flat Press Insulating Glass Machine High Speed Produce Smooth Running Images |